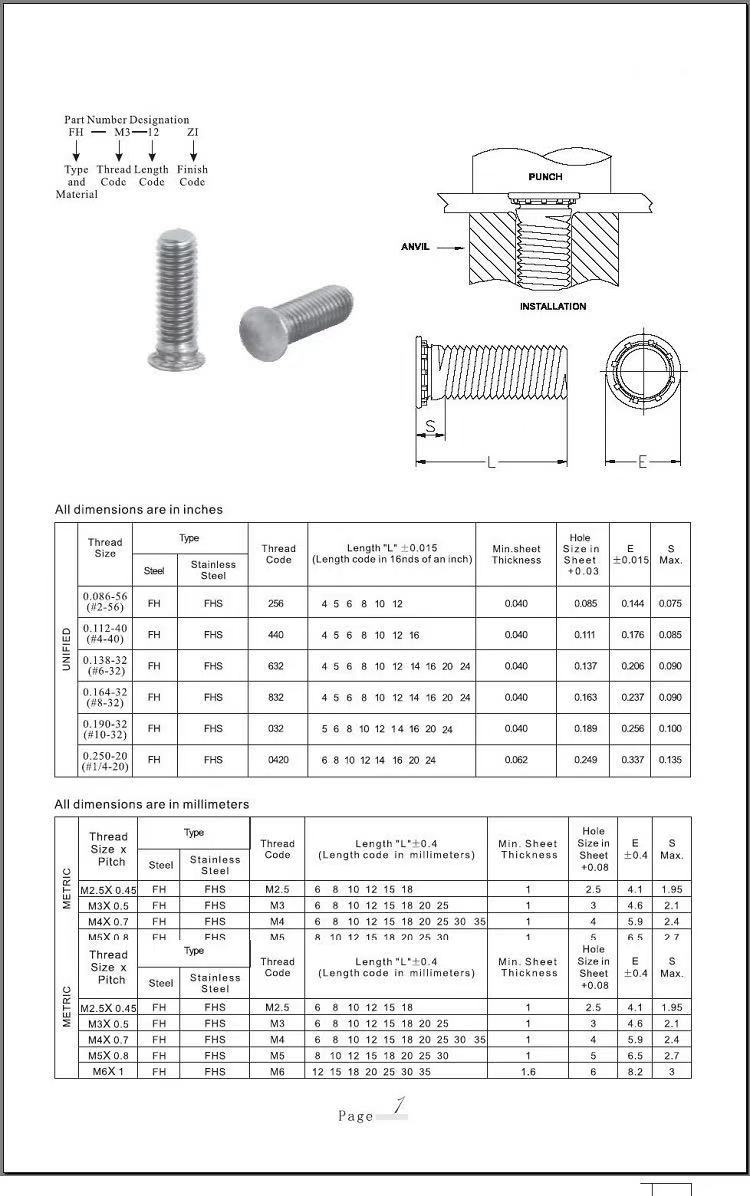

Products Specifications:

Self-Clinching Screw Description

FH (flush-head) Studs are installed by placing them in properly sized holes in the sheets and squeezing into place with any standard press.The squeezing action embeds the head of the stud into the sheet.The metal displaced by the head flows smoothly and evenly around the ribs and into the annular groove creating a flush head assembly and securely locking the stud into the sheet with high torque-out and pushout resistances.

FH4 & FHP (flush-head) Studs for Stainless Steel are designed to provide strong threads in stainless steel sheets as thin as .040" / 1 mm.Type FHP studs have high corrosion resistance.Both types are designed for use in stainless steel sheets with a hardness of 92 or less on the Rockwell "B" scale.

HFE (high-strength) Studs are designed with an enlarged head diameter to provide maximum pull through in sheets as thin as .040" / 1 mm.

HFHB Studs are ideal for applications which demand superior electrical/mechanical attachment points.Phosphor bronze studs offer twice the conductivity of carbon steel studs.